About Company

Supratama Aneka Industri (SAI) is implementing the latest technology in packaging industry, both for rigid and flexible solutions. Our products are designed for small to big size company, from local to multinational customers.

SAI was established in 1990 with main focus to provide rigid packaging for food and beverage industry. Company started with Thermoforming lines, continue growth with innovation in Dry Offset printing, Injection Molding, Blow Molding and In mold Label / IML.

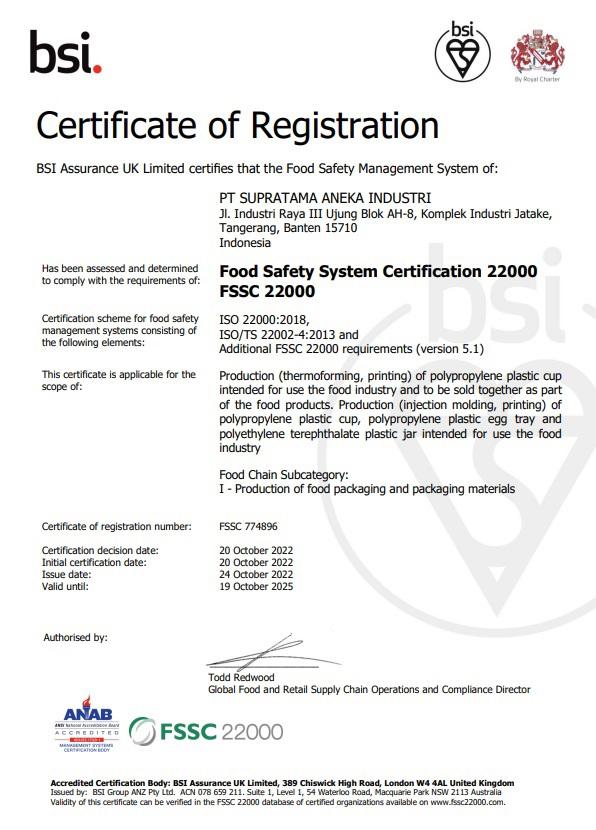

In 2023, SAI started operation for flexible packaging and B2C (Business to Consumer) channel distribution. Our Company has 2 factories which located in Tangerang and Boyolali. Certified FSSC 22000. Currently we manage around 600 employees.

Start operation with thermoforming lines, focus in water industry

Refocusing business to specialize in packaging for biscuit industry

Provide vacuum forming and IML packaging.

FSCC 22000 certified

Start operation for flexible packaging

Vision, Mission, Values

Vision

The best choice for high quality and eco friendly packaging

Mission

1. Always innovate to create safe, reliable, high quality and eco friendly packaging solutions

2. Continue to develop employee capabilities, production processes and technology

3. Contribute to the welfare of society, the surrounding environment and all related parties

Values

1. Committed

Having strong dedication and action to fulfill its promise to all stakeholders

2. Optimistic

Always put best effort, never give up to get the best outcome

3. Persuasive

Communicate, influence and collaborate with people to achieve goal

Factory

Cikupa Site

Jl. Industri Raya III Blok AH No.8, Tangerang 15710 • Banten • Indonesia

Boyolali Site

Desa Kenteng, RT 004, RW 004, Penggung , Boyolali, Kab Boyolali, Jawa tengah

Our Capability

RIGID PACKAGING

FLEXIBLE PACKAGING

Our Project

Printed Cup

In Mold Labelling Cup

Double Chamber Cup

Jar

Bowl

Egg Laminate

Printed PVDC

Rice Bag

Our Equipment

THERMOFORMING LINE

In line Thermoforming machine. Output ~20 million pcs/month

INJECTION MOLDING LINE

Plastic injection machine

BLOW MOLDING LINE

Blowing Machine

DRY OFFSET PRINTING

8 color Cup Printing

IN MOLD LABELLING MACHINE

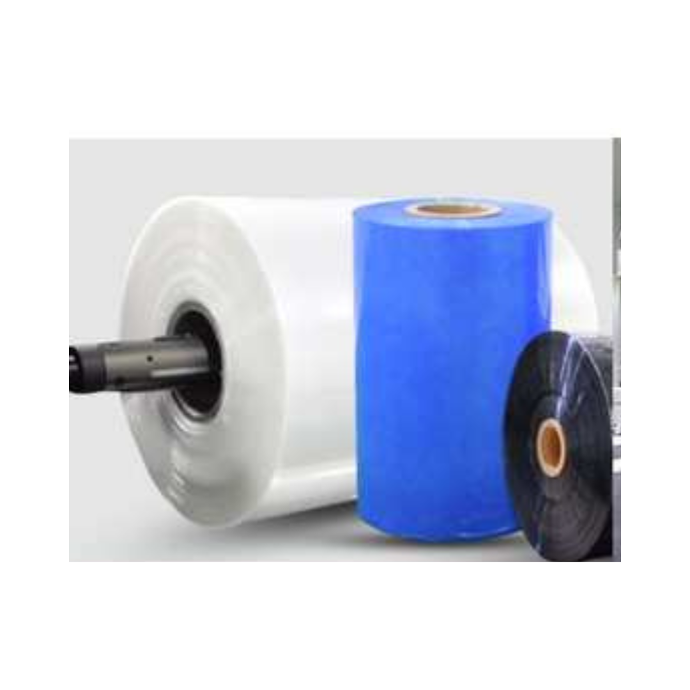

MULTILAYER CO-EX FILM

- 3 to 11 layers coex film

- Nylon or EVOH as barrier layer

- Offer both thermoforming film and curling resistant lidding film

- Offer both low temperature resistant and heat resistant retort film

- 7 layers coex blown film line

- 9 layers coex blown film line

- 11 layers coex casting film line

- Vacuum packaging thermoforming film

- Anti-curling lidding film

- Liquid packaging film

- Excellent puncture resistance film for meat packaging (resist to meat bone)

- Air tight cushion film

- Thickness range : 40 ~ 300 micron

- Rich product line to meet various customer specification

MAP HIGH BARRIER LIDDING FILM

Lid Tech Soft high barrier anti-fog film is a lidding for modified atmosphere packaging. Lidtec Soft high barrier anti-fog fil is produced by art-of-state eleven layers coextrusion technology. It has excellent optical properties and anti-fog function, which presents freshness and quality of food products perfectly.

Product specs :

- Thickness : 25 micron

- Width range : 300 ~ 830 mm

VACUUM SKIN PACKAGING FILM

VSP film is suitable for chilled or frozen meat products, seafood and fish, ready meals, etc. Depending on the application scenario, we offer both high barrier skin packaging films. Our VSP film has excellent glossiness, high clarity. excellent thermo-forming and toughness at low temperature. It looks like the second layer of the skin wrapping the product tightly. It greatly reduces the juice leakage of fresh meat, maintain the high quality and original taste of meat with perfect presenting to consumers.

Product specs :

- Thickness : 70 ~ 150 micron

- Width range : 2500 ~ 1200 mm

POLYOLEFIN VACUUM THERMOFORMING FILM

Our polyolefin thermo-forming film is fully recyclable. We developed a non-nylon film structure to achieve an environmental friendly solution of vacuum thermo-forming package. Our polyolefin thermo-forming film has excellent low-temperature puncture resistance. It is softer and tougher than traditional nylon thermoforming film at frozen environments. It performs better for vacuum packaging of poultry and frozen meat.

Product specs :

- Thickness : 70 ~ 200 micron

- Width range : 250 ~ 1200 mm

POUCH PACKAGING

LAMINATION FILM & STAND UP POUCH

Loyal Costumers

Certification

FSSC 22000

Food Safety System Certification 22000, is a recognized international standard for food safety management systems.

It specifies the requirements for a comprehensive system that helps organizations in the food industry ensure the safety of their products throughout the entire food supply chain, from production to distribution.

This certification is designed to demonstrate a commitment to food safety and compliance with industry best practices.